Daedalus D100

sea / sun / wind / water

Advances in technology have led to dramatic improvements in sailing performance.

All previously long held records have been smashed.

New standards of ocean-going speed have been re-set to new and incredible levels.

Daedalus combines speed, comfort, and green technology.

The first Daedalus D100 is currently being built at our shipyard in Edenton, NC

The first Daedalus D100 is currently being built at our shipyard in Edenton, NC

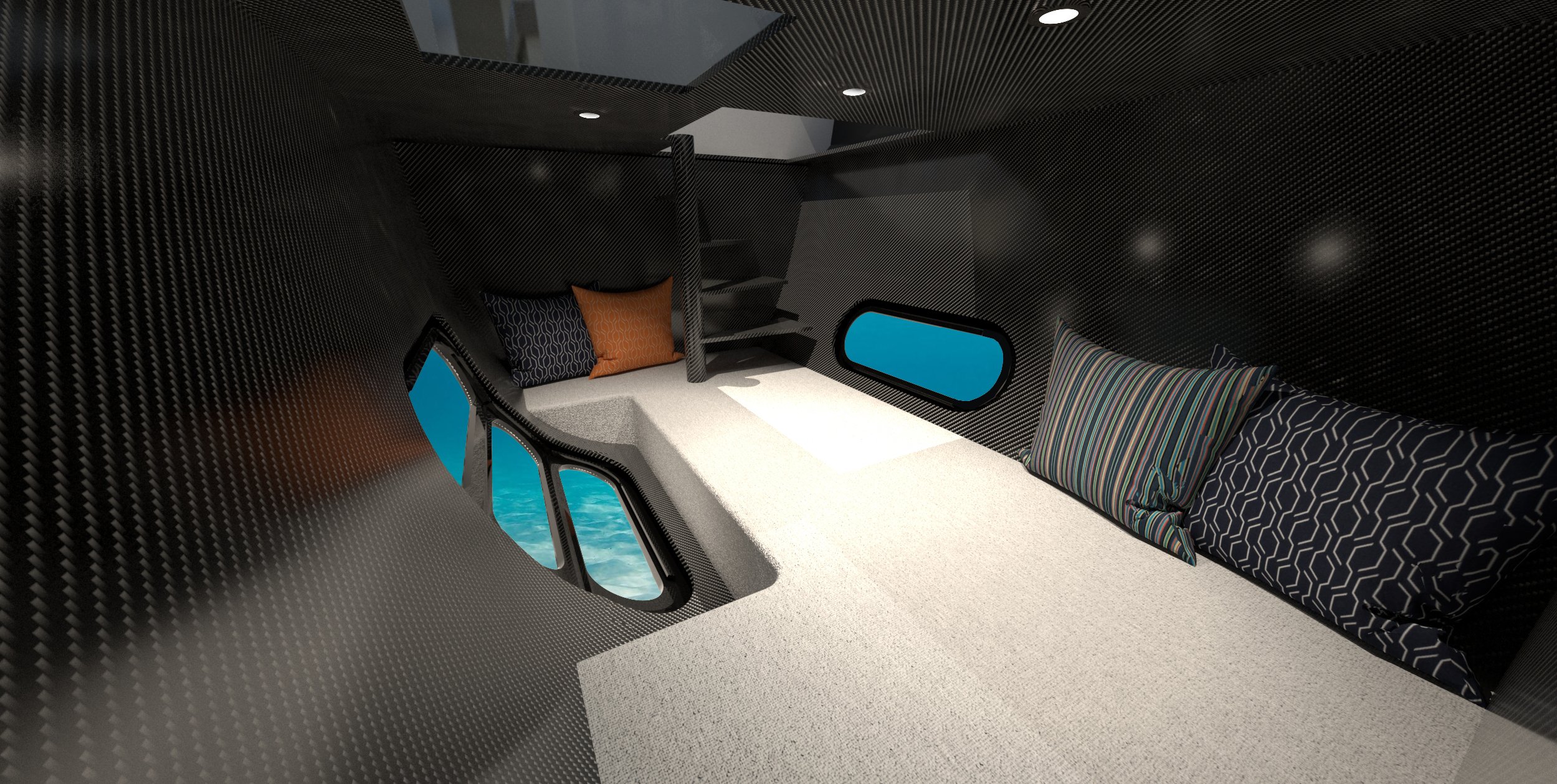

Take a look inside

Swipe to look around and tab the circles to move to another view.

NEW ENGINEERING STANDARDS

A Global Shift To Fossil Free Exploration With Cutting-Edge Design

At Daedalus, new design concepts, cutting-edge engineering, and new systems integration have been applied to achieve an extremely high quality, comfortable, safe, clean and green performance catamaran for blue water sailing.

Industrial techniques similar to aerospace and automotive production lead to better engineering, better functionalities and a controllable, reliable quality of structural parts and systems.

The owner gets an attractive yacht with a high degree of customization. The key concepts behind the design and engineering choices are simplicity, reliability and easy/low maintenance. Finite element (FE) calculation methods were used to study stress areas and optimize fiber orientation, laminate weights, and structures using high-security factors.

Computational Fluid Hydrodynamics (CFD) allowed the optimization of the flow along the hull and around foils, to find the best configuration of drag, lift, stability and control. The hulls are not designed to any rule but more to be balanced, fast and forgiving under all conditions.

Our 3D-design enables perfect geometry definition and control and a parallel development process using the expertise and experience of numerous design and engineering groups worldwide at the same time.

CLEAN ENERGY ONBOARD

Energy Generation Via Solar Cells, Hydro Re/Generation and Wind Turbines

Hydrogen is generated onboard and the energy is stored in lithium battery banks.

The Process

We take seawater, highly purify it, then using a PEM-proton exchange membrane, the pure deionized water (H2O) is split into its constituent parts, hydrogen (H2) and oxygen (O2), via an electrochemical reaction.

A DC voltage is applied to the electrolyzer, water is fed to the anode (or oxygen electrode) and is oxidized to oxygen and protons, releasing electrons. The protons (H+ ions) pass through the PEM to the cathode (or hydrogen electrode), where they meet electrons from the other side of the circuit and are reduced to hydrogen and stored in carbon-fiber reinforced tanks thus drastically improving weight to storage ratios.

When then the batteries are in need of more energy than is being provided from nature outside, air is delivered to the fuel cell stack. Hydrogen travels from the tanks to the fuel cell stack. There, it goes through a chemical reaction involving the oxygen in the air, and the resultant current is used to recharge the batteries.